Liquid Silicone Rubber (LSR) is a high-purity, platinum-cured silicone material supplied in a liquid form. This unique state unlocks exceptional capabilities beyond those of traditional solid silicone rubber. Renowned for its safety, non-toxicity, and durability, LSR’s fluid nature is the key to its superior performance in precision manufacturing.

Why Choose Liquid Silicone Rubber? Key Advantages

- Unmatched Purity and Transparency: The LSR manufacturing process requires minimal additives, preserving the material’s inherent clarity and high purity. Supplied in sealed containers, it is protected from contamination, making it ideal for sensitive applications like medical devices and optical lenses.

- Exceptional Precision and Detail Reproduction: In its liquid state, LSR effortlessly flows into the most intricate details of a closed mold. The injection molding process, controlled by precise computer dosing, ensures minimal flash (excess material) and guarantees tight dimensional tolerances for complex parts.

- Eco-Friendly and Efficient Production: LSR is inherently non-toxic. The high-efficiency molding process generates almost no waste material, supporting sustainable manufacturing goals and reducing environmental impact.

LSR vs. Solid Silicone Rubber: Selecting the Right Material

Your project’s requirements determine the best material choice. Here’s a clear comparison to guide you:

| Feature | Liquid Silicone Rubber (LSR) | Solid Silicone Rubber |

|---|---|---|

| Manufacturing Process | Fully automated injection into a closed mold. | Often involves manual placement of material in an open mold. |

| Precision & Tolerances | Excellent. Computer-controlled for high accuracy and minimal flash. | Good. More challenging to control; typically more flash and parting lines. |

| Surface Finish | High clarity, seamless appearance, minimal visible injection points. | Often semi-translucent, visible parting lines, and flash that may need trimming. |

| Typical Applications | Precision parts, high-transparency products, medical implants, food-grade items. | Industrial seals, gaskets, multi-color buttons, larger, less complex components. |

Ideal Applications for Liquid Silicone Rubber

LSR is the material of choice for demanding industries where performance, safety, and precision are critical.

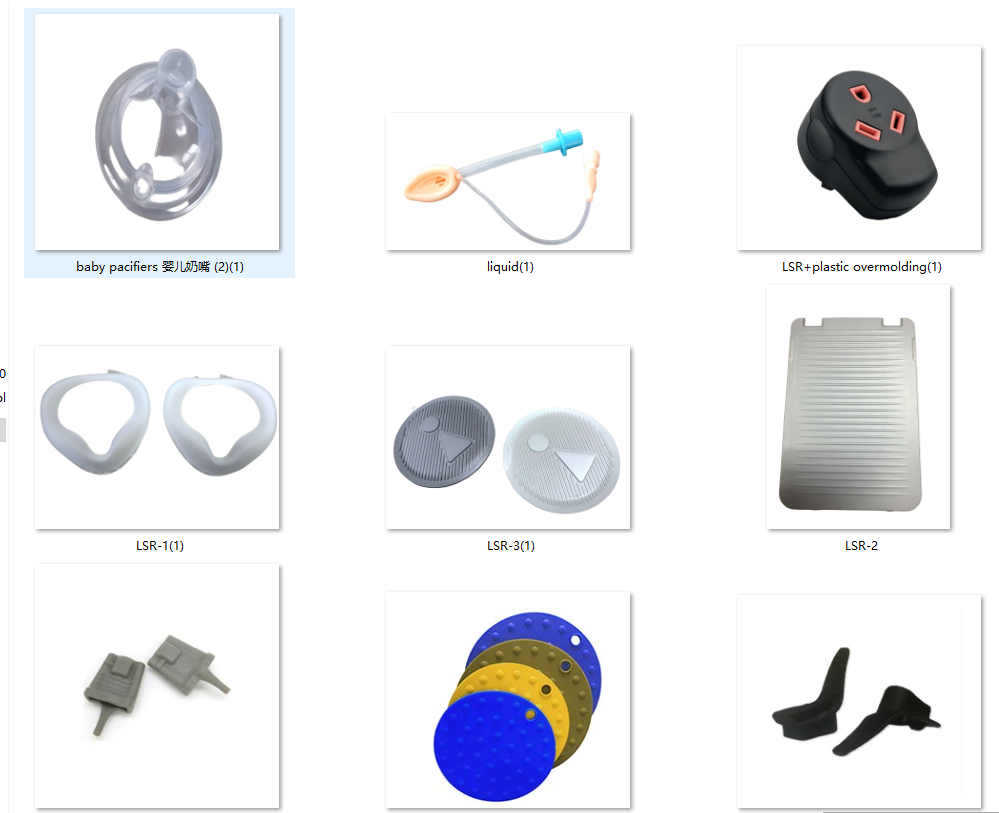

- Medical & Healthcare: Syringe pistons, respiratory masks, implantable devices, and surgical tools benefiting from LSR’s biocompatibility and sterility.

- Optics & Lighting: Lenses, light guides, and seals requiring high light transmission and environmental resistance.

- Infant & Food Contact: Baby bottle nipples, pacifiers, kitchen utensils, and bakeware that demand absolute safety and non-toxicity.

- Automotive & Electronics: Seals, gaskets, and sensor components that must withstand extreme temperatures and harsh environments.

Is LSR the Right Solution for You?

If your project involves complex geometries, demands a superior surface finish, operates in a high-performance environment, or requires the highest levels of purity, then Liquid Silicone Rubber is likely the optimal material.

Partner with Us for Your LSR Projects

At Rilong, we specialize in high-precision Liquid Silicone Rubber injection molding. Our expertise and advanced manufacturing capabilities ensure that your products meet the strictest quality and performance standards.

Ready to innovate with LSR? Contact us today for a consultation or to request a quote. Let’s turn your ideas into high-performance reality.