High-End Silicone Consumer Products

Inventors and engineers rely on Rilong Molding for silicone injection molding applications that require innovation and attention to detail.

Turn concepts into market-ready products faster with our end-to-end prototyping and manufacturing solutions. We bridge the gap between idea and mass production by providing:

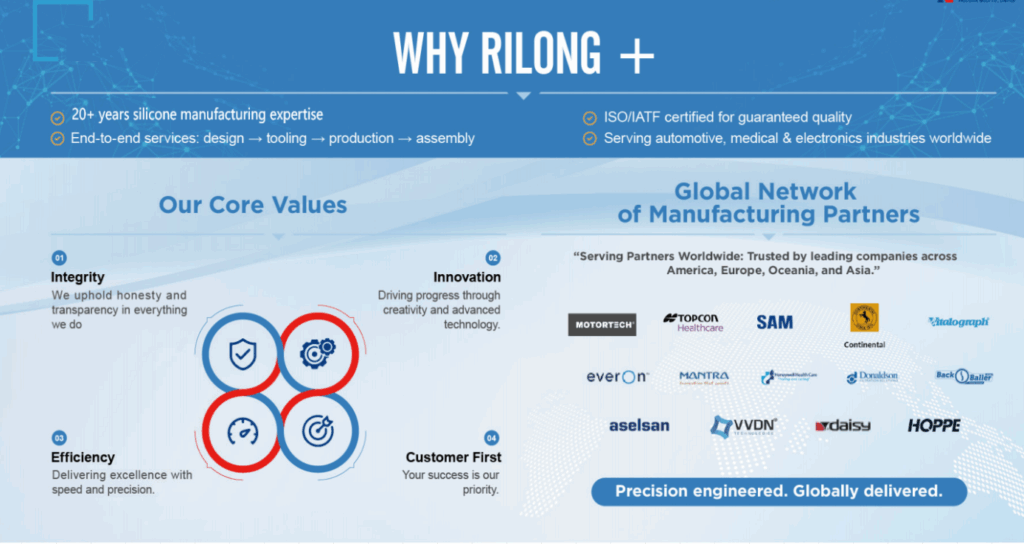

Why Partner With Rilong?

We help you mitigate risk (via market-ready prototypes), accelerate production (2-5X faster than traditional workflows), and cut costs (by validating designs upfront to prevent tooling reworks)—turning your concept into a market-ready product through integrated engineering, prototyping, and manufacturing