Custom Silicone Solutions – Precision-Tailored for Your Needs

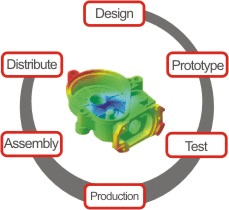

At Rilong, we bridge the gap between your ideas and market-ready products through precision-engineered silicone solutions. We are very specialized in solving complex silicone customization challenges, offering end-to-end solutions from design to delivery. Our expertise ensures your product meets exact specifications while optimizing cost, performance, and time-to-market.

Prototyping & Design Optimization

3D CAD Analysis & Mold Development: We transform your concepts into actionable designs, analyzing manufacturability and performance through advanced 3D modeling.

Risk-Free Sampling: Test functionality with prototypes before mass production—no more guesswork or wasted procurement costs.

Transparent Pricing: Receive instant quotes based on existing samples or drawings, with no hidden fees.

We Solve:

✔ Trade procurement inefficiencies | ✔ Unverified product suitability | ✔ Design-to-production gaps

Design For Manufacturability

Optimizes designs for easy, cost-effective manufacturing

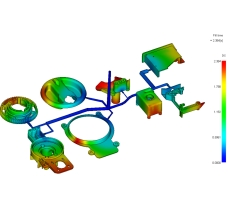

Moldflow Analysis

Simulates molding to prevent defects and save time

Problem-Solving Customization

Performance Solutions: Tailor material blends (food-grade, medical, industrial) and molding techniques.

We Answer:

Performance & Material Optimization

Leveraging 20+ years of industry experience, we address critical quality issues:

Material Enhancements: Improve elasticity, transparency, tensile strength, UV/heat resistance, and anti-aging properties.

Functional Upgrades: Redesign for better usability, durability, and cost-efficiency.

We Fix:

Transparent, Eco-Friendly Production

Green Manufacturing: Solvent-free processes and ISO-certified workflows(ISO9001, ISO14001, TS16949 ).

We Clarify:

10px