INDUSTRY-LEADING

Advanced Silicone Solutions for Next-Generation Applications

With over 20 years as China’s foremost silicone molding innovator, Rilong Precision Mold Company delivers industry-leading molding expertise both in hot compression molding and LSR injection molding, backed by:

22+

Years of Experience

99%

CONSUMER ACCEPTANCE RATE

800+

Projects Executed

12K+

Happy Customers

One-Stop Solution — From Initial Design to Final Assembly

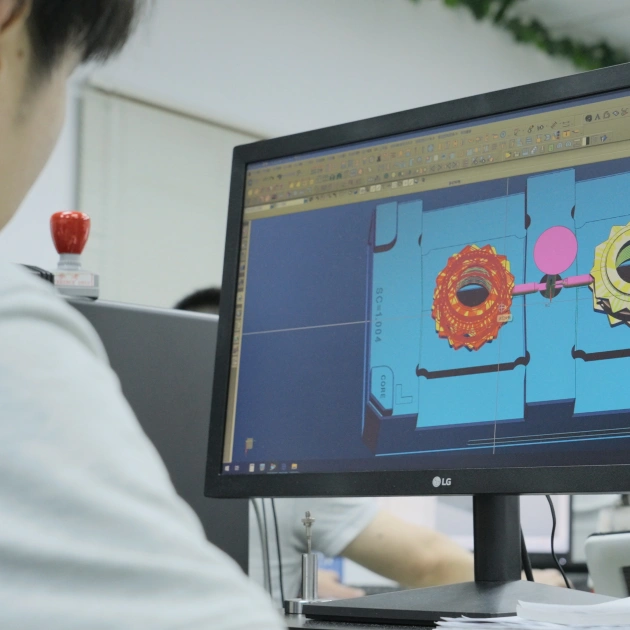

01 – Design & Prototyping Support

Early Involvement

We provide early design support, offering insights to optimize manufacturing and boost product performance. Our engineers collaborate as an extension of your team, ensuring a deep understanding of your product and its components from the start.

02 – Extreme Molding Capabilities

Liquid Injection Molding

Our technology-driven facility consists of fully automated liquid injection molding cells featuring premium molds, a class 8 clean room for hygienic production requirements, and inline post-molding stations for value-added processes.

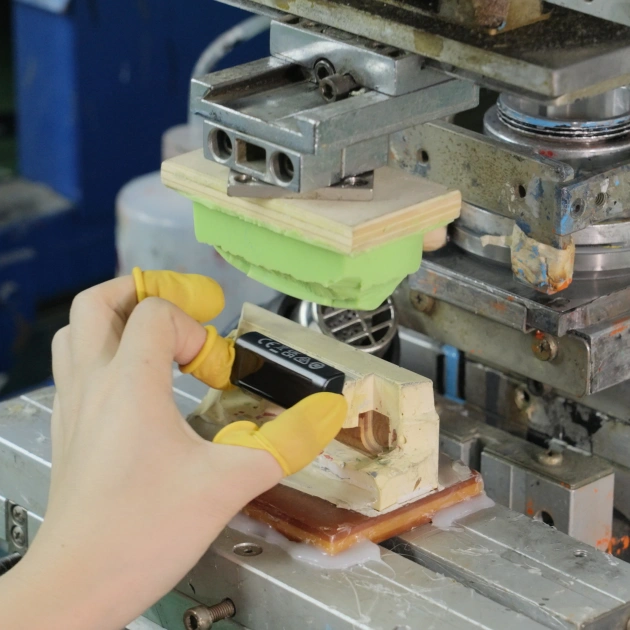

03 – Value-Added Processes

Value-Added Processes

Our value-added services cover the full product development cycle—from design & prototyping (3D/CNC/soft tooling) to post-processing (finishing, printing, coating, laser etching) and custom packaging. As customer needs diversify, we provide seamless one-stop solutions, ensuring quality, efficiency, and customization at every step.

04 – Quality Control Process

Quality Assurance

The key factors that enable us to maintain our high quality standards are the implementation of rigorous systems across our entire factory operations, including ISO 9001, ISO 14001, ISO 13485, and the 7S Management System. Additionally, all materials comply with RoHS, UL, and other relevant certifications.

Why RilongSilicone

0

Built Internally

Our priority is the satisfaction of our customers, and therefore, we provide you with weekly updates so that you are aware of the current stage of your project.

Oct 7, 2024

0

Yield Rate

A low-quantity order helps you explore the market before investing in large quantities.

Sep 20, 2024

0

Consumer Acceptance Rate

We start from your understanding as our input, and we evaluate new products through our end-to-end solutions that cover the entire product development process from product ideation and design to tooling, testing, and product manufacturing.

Aug 15, 2024

Trusted by

Design

CAD Drawing Services

Production

Compression Molding

Liquid Silicone Rubber Custom Component Solutions

Rilong Silicone offers complete turnkey solutions for any business in need of high-performance liquid silicone rubber (LSR) injection molded parts. We can help you choose the right material for your upcoming project, as well as provide you with tooling solutions that are best for your ongoing production needs.